Seal Trimming Machine

Seal Trimming Machine

- IMTPL manufactures high quality Seal Trimming Machine with auto control where the operator is required to provide & draw out the products ,so even a fresh worker can operate the machine easily.

- It consists of two cutters for ID/OD of seal. The machine has got features for easy setting & with precise and accurate dimensions therefore products are upto the international standards.

- The high quality of production ensures the strength of the machine that is why it can be operated for 24 hours continuously.

- All the above features ensure that your production costs are lower than ever.

- IMTPL provides you all this at a very reasonable price alongwith prompt delivery and excellent after sales services.

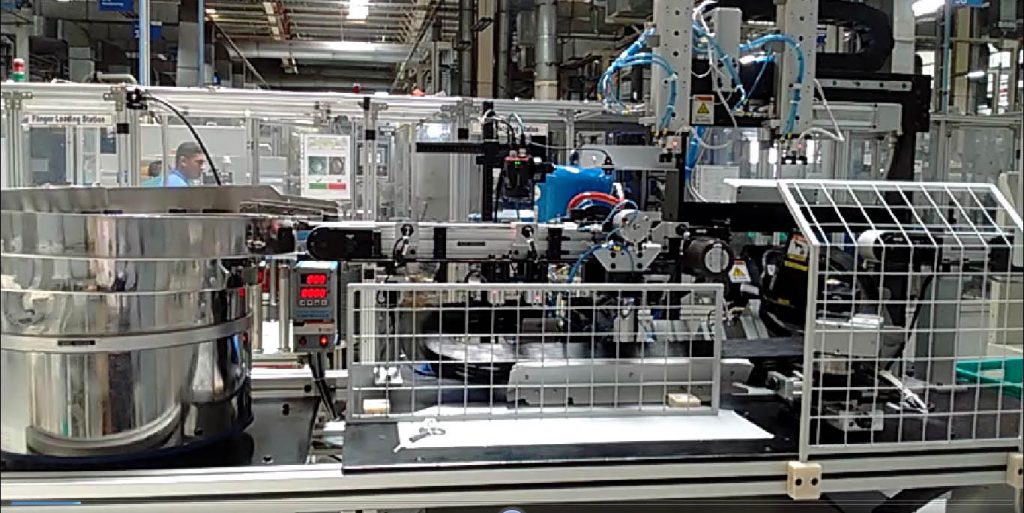

Automated trimming system is mainly design for automatically feed the seals to a trimming head, where the main lip is trimmed and the seals are collect in a bin.

The operator loads the seals on the bowl feeder. The seals moves one by out of the bowl into the inlet conveyor. The stopper cylinder 2 stops the seal at orientation checking station and the stopper cylinder 1 hold the next coming seal. Camera checks the seal orientation. If the seal orientation is not correct, the clamping cylinder holds the seal and rotary cylinders rotate to take seal correct position. The seal moves to next and stop with the support of Y stopper at pick and place position 1. If seal found correct at orientation checking, then the stopper cylinder 2 retract and seal goes to Y stopper at pick and place.

The pick and place gripper 1 pick the seal from inlet conveyor and load it on trimming head. The trimming head index by 180 degree to offer the seal vertical position for trimming operation.

The seal rotate at a set RPM , and an electrically operated trimming head with blade mounted on it advanced to trim the seal lip. The trimming head index back to horizontal position. The pick and place gripper 2 picks the trimmed seal and drop it to next exit conveyor. the conveyor moves the seal to the final bin.

The pick and place have two vertical axes with grippers. While one seal is being loaded to the trimming unit, the finished one dropped at the exit conveyor. Similarly the spindle stations have 2 servo driven spindles. When the seal is unloaded / loaded on the horizontally aligned fixture, the lip is being trimmed on the vertically aligned fixture.

Entire system can be making it portable to be towed wherever is required.

Castor wheels orientation can be fixed lateral direction. Direction of the castor wheels can be fixed by provided manual brake.

Proximity switches are provided for seals availability and indexing fixture identification.

Spindle servo motors have an integral fail safe brake as a safety device in case of power outage condition

Motors are controlled by means of servo drive, motion controller with suitable software as per the instructions /, inputs.