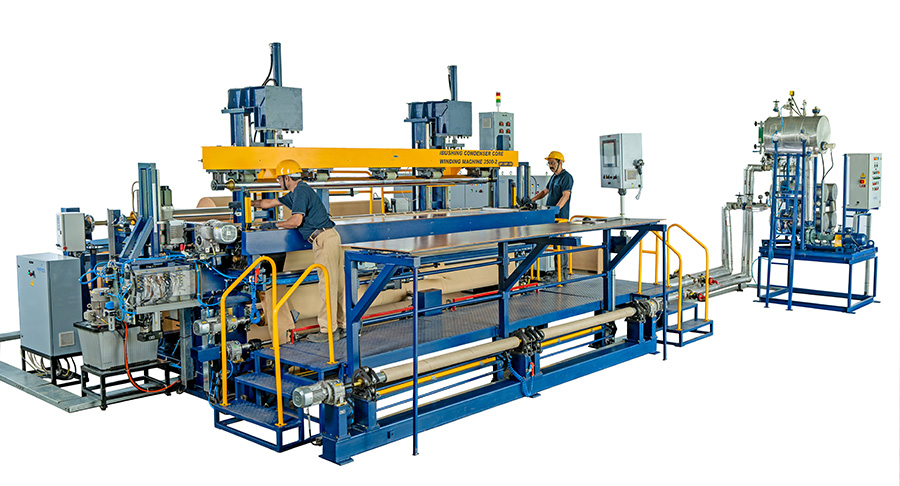

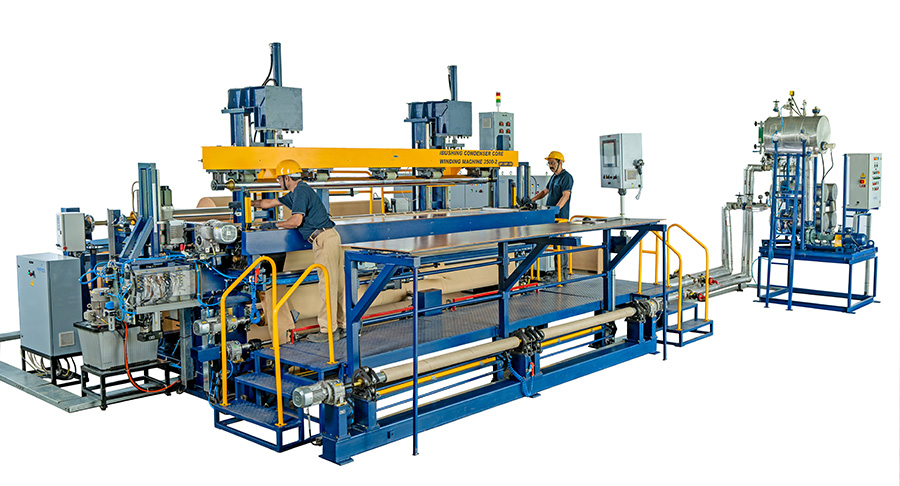

RIP-RIS Bushing condensor Winding Machine

RIP-RIS Bushing Condensor Winding Machine Manufacturer

Intel Motion has been manufacturing high-quality RIP-RIS-bushing condensor winding machines with precise engineering and technology for years as per customer requirements. Bushing winding machines manufactured by us are successfully running in many companies in India.

At Intel Motion we design and manufacture RIP- RIS-bushing condensor winding machines according to your requirements for different lengths and with different levels of automation as per your requirement.

Bushing winding machine

This machine is used to wind condenser core for OIP bushings with one un-coiler (web).

The maximum 3500mm paper can be used as un-coiler.

Decoiler is controlled by magnetic brake with a feedback of load cell.

The central part of machine is consisting of solid steel frame on which bottom heated rollers, top pressure roller assembly, Cutter assembly are mounted.

Bottom heated rollers are heated with Thermic oil. Temperature of the heated oil will be 110 deg.

Top pressure roller heating is optional.

The cutters are cutting the paper in right length. The paper ends are cut in straight, in steps or cone. Step cutting and cone cutting is possible on both sides.

The reference line of the machine is always the Oil side of the bushing.

Top pressure roller movement is controlled by hydraulic system. The specific pressing force is adjustable in steps and remains constant throughout the winding.

One foil guide shows the exact position of foil insertion. Second side laser foil guide is optional.

Accurate diameter measurement guarantees correct insertion of aluminum foil.

Separate Industry standard control cabinets for controller+ servo drives, VFDs & IR heater (optional)

Depending on customer`s requirement machine can be equipped with optional features

o Infra red heating system to dry paper during winding, which reduces the time for drying in autoclave.

o Laser guide for another end of foil, to ensure correct foil insertion.

o Second Decoiler unit.

o Top pressure roller heating

Bushing winders – or: winding machines for condenser bushings – are used to wind insulating bodies for Resin Bonded Paper or Oil Impregnated Paper condenser bushings from kraft or crepe paper and aluminum foil.